Precision-Crafted Birth Month Flower & Birthstone Necklaces: Innovation in Stainless Steel

Explore the advanced materials and cutting-edge technologies behind custom stainless steel jewelry, from corrosion resistance to eco-friendly manufacturing.

As the demand for personalized, durable, and sustainable jewelry continues to rise, the use of high-quality materials and advanced manufacturing technologies has become crucial in the production of custom birth month flower and birthstone necklaces. These pieces of jewelry, loved for their sentimental value, now benefit from innovation in material science and manufacturing processes. This article will dive into the unique properties of stainless steel, with a focus on the superior corrosion resistance of 304 and 316L grades, and explore how modern technologies like laser cutting, hydraulic processes, and environmentally-friendly production methods are transforming the jewelry industry.

The Superiority of Stainless Steel in Custom Jewelry Manufacturing

Stainless steel is one of the most sought-after materials in the jewelry industry due to its durability, strength, and versatile design potential. When creating custom birth month flower and birthstone necklaces, the material’s resistance to corrosion and wear is essential, as these necklaces are worn daily and need to maintain their pristine appearance over time.

Stainless steel alloys, particularly 304 and 316L, are frequently used in jewelry manufacturing due to their excellent corrosion resistance, strength, and aesthetic qualities. While both are highly durable, they exhibit different characteristics that make them suited to specific applications.

304 Stainless Steel: A Popular Choice for Custom Jewelry

304 stainless steel is one of the most common materials used in the creation of jewelry. Known for its excellent corrosion resistance and malleability, 304 steel is often used for fashion jewelry, where it is exposed to light to moderate wear. Its ability to withstand oxidation, rust, and staining makes it ideal for pieces like custom birthstone necklaces that will be worn in varied environments. However, while 304 stainless steel provides adequate protection against the elements, it does not offer the same level of resistance as the higher-grade 316L steel.

316L Stainless Steel: The Premium Option for Long-Lasting Jewelry

316L stainless steel, also known as marine-grade steel, is superior to 304 in terms of corrosion resistance. It is particularly well-suited for jewelry that will be exposed to harsh conditions, such as saltwater, sweat, or extreme humidity. This makes it the ideal choice for creating premium, custom birth month flower necklaces intended to withstand daily wear and environmental stressors. The added element of molybdenum in 316L steel enhances its resistance to chlorides, further protecting the jewelry from corrosion.

Choosing Between 304 and 316L for Custom Birthstone Necklaces

- 304 Stainless Steel: Best for fashion jewelry with moderate exposure to moisture or chemicals.

- 316L Stainless Steel: Ideal for long-lasting, high-end jewelry that requires extreme resistance to corrosion, particularly in harsh environments.

Advanced Manufacturing Techniques in Stainless Steel Jewelry

The design and manufacturing processes behind stainless steel jewelry have evolved significantly, incorporating cutting-edge technologies to meet the growing demand for intricate, durable, and eco-friendly custom pieces. From precise cutting techniques to advanced finishing methods, the possibilities for creating customized birth month flower and birthstone necklaces are nearly limitless. Below, we explore some of the key technologies driving the evolution of stainless steel jewelry manufacturing.

Laser Cutting: Precision and Detail in Every Design

Laser cutting is one of the most commonly used techniques in modern jewelry manufacturing. This high-precision method allows designers to create intricate, detailed designs with minimal waste. Laser cutting is particularly advantageous for custom birthstone and birth month flower necklaces, where intricate patterns, fine lines, and precise cuts are essential. The process involves using a focused laser beam to melt or vaporize stainless steel along the desired path, resulting in a clean, smooth edge without the need for additional finishing.

One of the key benefits of laser cutting is the ability to work with small, delicate pieces, which is critical when crafting custom charms and intricate flower designs. Furthermore, laser cutting can be applied to both 304 and 316L stainless steel, making it a versatile and valuable technology for manufacturers looking to produce high-quality custom necklaces.

Hydraulic Processes: Shaping Stainless Steel with Power and Precision

Hydraulic processes, such as hydroforming and stamping, are often used to shape and mold stainless steel into complex forms. In the context of custom jewelry, these processes are employed to create three-dimensional flower shapes, intricate prongs for birthstones, and other elements that require both strength and precision. Hydraulic presses can mold the steel at high pressures, ensuring that each piece maintains structural integrity while also allowing for detailed, artistic designs.

This process is particularly useful when creating custom pendants or charms that require a high degree of precision in their final shape, all while ensuring the piece remains strong and resilient against wear and tear.

Eco-Friendly Production: Sustainability in Jewelry Manufacturing

With the increasing emphasis on sustainability in manufacturing, the jewelry industry has made significant strides in adopting eco-friendly production processes. One of the key innovations is green electroplating, which uses environmentally-friendly chemicals and processes to coat stainless steel pieces with a thin layer of precious metals such as gold or silver.

Unlike traditional electroplating methods, green electroplating minimizes harmful waste and reduces the use of toxic substances. This technology has made it easier for manufacturers to produce high-quality, custom birthstone and flower necklaces that are not only beautiful and durable but also environmentally responsible.

Another important aspect of eco-friendly production is waste recycling. In modern manufacturing facilities, the recycling of materials such as excess metal shavings and scraps has become a standard practice. These materials are often repurposed, reducing the environmental impact of production and contributing to a circular economy. This makes stainless steel jewelry, including custom birth month flower necklaces, a sustainable choice for both manufacturers and consumers.

Corrosion Resistance in Real-World Scenarios: Case Studies of Stainless Steel Jewelry

The corrosion resistance of stainless steel plays a significant role in the longevity and durability of custom birthstone and flower necklaces. In real-world applications, this resistance becomes especially important when the jewelry is exposed to sweat, humidity, or harsh outdoor conditions. Below, we look at case studies of jewelry pieces that successfully utilized 304 and 316L stainless steel to meet the demands of various environments.

Case Study 1: Outdoor Adventure Jewelry Using 316L Stainless Steel

A well-known outdoor brand partnered with a jewelry manufacturer to create a line of custom necklaces with birthstones for outdoor enthusiasts. The pieces were designed to withstand exposure to saltwater, sweat, and extreme temperatures, making 316L stainless steel the ideal material for the job. The result was a line of highly durable, corrosion-resistant necklaces that have become popular among adventurers who need jewelry that will last through rugged conditions.

Case Study 2: Fashion Jewelry with 304 Stainless Steel

A leading fashion jewelry brand chose 304 stainless steel for a limited-edition collection of custom birth month flower necklaces. These pieces were designed with delicate floral engravings and colorful birthstones, intended for daily wear but not for exposure to extreme conditions. The corrosion resistance of 304 steel provided adequate protection against everyday wear, while the laser cutting technique allowed for the intricate designs to shine.

Conclusion: The Future of Custom Stainless Steel Jewelry

As demand for personalized, durable, and eco-friendly jewelry grows, the role of stainless steel in the creation of custom birth month flower and birthstone necklaces will continue to expand. The use of 304 and 316L stainless steel, paired with advanced technologies like laser cutting, hydraulic processes, and green electroplating, ensures that manufacturers can produce high-quality, long-lasting, and environmentally responsible jewelry.

For B2B customers in the jewelry industry, partnering with manufacturers who leverage these innovative materials and techniques will allow for the creation of stunning, customized jewelry that stands the test of time. By focusing on durability, precision, and sustainability, businesses can offer consumers high-value products that reflect both personal sentiment and cutting-edge design.

Ready to elevate your jewelry offerings with precision-crafted, custom stainless steel birthstone and flower necklaces? Reach out to our team today to learn more about how our advanced materials and technologies can help you create the perfect jewelry collection.

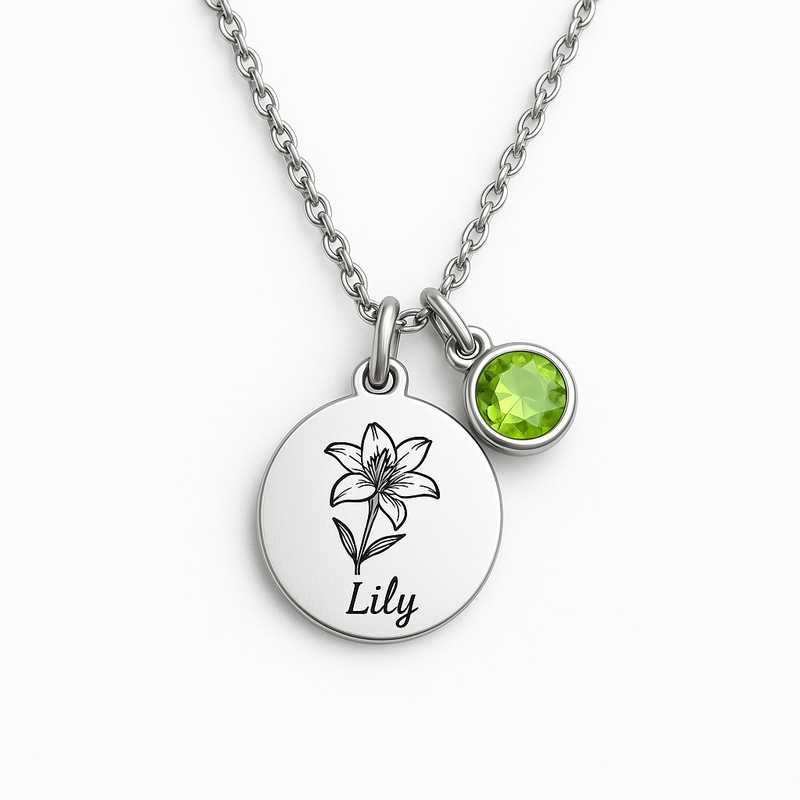

Featured Image Prompt

Prompt for Featured Image: A highly detailed, close-up image of a stainless steel birthstone and flower necklace, showcasing seamless metalwork with perfect symmetry. The necklace should be on a white background, highlighting the intricacy of the floral design and the clarity of the birthstone. The image should focus on the high-quality finish, with no imperfections, and emphasize the sleekness and precision of the stainless steel craftsmanship.