The global demand for durable, stylish, and low-maintenance jewelry has surged in recent months, with waterproof designs becoming a key trend across online and offline channels. For B2B buyers, especially brands and wholesalers, the waterproof gold plated necklace category is no longer a niche product but a core revenue driver. Consumers are actively searching for jewelry that can be worn daily without tarnishing, fading, or losing its shine.

This shift creates strong opportunities for OEM/ODM stainless steel jewelry manufacturers to support business clients with scalable production, flexible customization, and reliable quality control. From minimalist pendants to symbolic charms, stainless steel is proving to be the ideal base material for modern gold-plated jewelry collections.

In this article, we explore why waterproof designs are trending, how popular styles like the 18k gold initial letter charm and stainless steel star charm necklace fit into current market demand, and how OEM/ODM partners can help jewelry businesses grow efficiently.

Over the past month, social media platforms and e-commerce marketplaces have shown a clear increase in demand for waterproof jewelry. Consumers want pieces they can wear while showering, swimming, or exercising, without worrying about discoloration or skin irritation. This has made the waterproof gold plated necklace one of the most searched and requested product types.

From a manufacturing perspective, stainless steel combined with advanced PVD gold plating offers a stable and cost-effective solution. Compared to brass or alloy, stainless steel provides superior corrosion resistance, making it ideal for waterproof applications. This directly supports brand claims around durability and long-term wear.

For wholesalers and retailers, waterproof positioning also reduces return rates and after-sales issues. Products that maintain their appearance over time build trust, encourage repeat purchases, and strengthen brand reputation in competitive markets.

Stainless steel has become the backbone of modern OEM/ODM jewelry production. Its mechanical strength, smooth surface, and resistance to oxidation allow manufacturers to produce consistent, high-quality gold plated necklaces at scale. This is particularly important for a waterproof gold plated necklace that must perform under daily exposure to water and sweat.

In OEM/ODM factories, stainless steel components are precision-cut, polished, and cleaned before plating. This preparation ensures strong adhesion of the gold layer, which is essential for maintaining color stability. Quality control teams typically conduct salt spray tests and wear simulations to validate waterproof performance.

For B2B clients, stainless steel also enables stable pricing and supply. Raw material costs are more predictable than precious metals, allowing brands to plan collections and wholesale pricing with greater confidence.

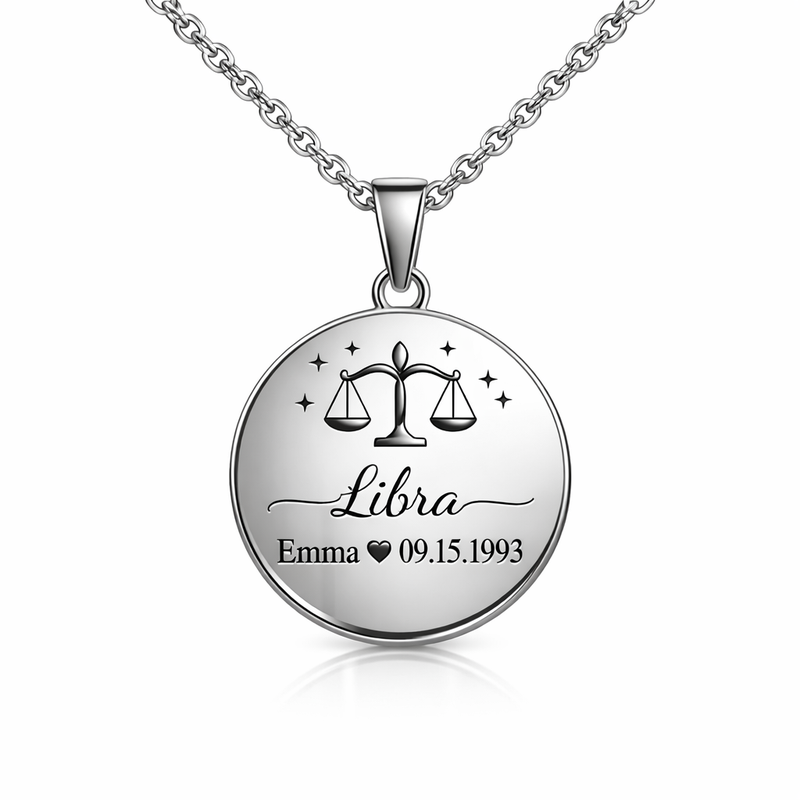

Personalization continues to dominate jewelry trends, and the 18k gold initial letter charm remains one of the most requested custom elements. Initial charms appeal to a wide range of consumers, from gift buyers to those seeking meaningful everyday accessories.

From an OEM/ODM standpoint, producing an 18k gold initial letter charm in stainless steel offers flexibility in font styles, sizes, and surface finishes. Laser cutting and CNC engraving allow for precise letter shapes, while PVD plating delivers the rich tone associated with 18k gold.

Many B2B clients choose to integrate initial charms into a waterproof gold plated necklace line, positioning the product as both personal and practical. Low MOQ options make it easier for brands to test multiple letter designs without high inventory risk.

Factories can also support private labeling, packaging customization, and exclusive design services, helping brands differentiate their initial charm collections in crowded marketplaces.

Symbolic motifs are another strong driver of sales, with celestial designs gaining popularity in recent trend reports. The stainless steel star charm necklace has emerged as a versatile piece that appeals to both minimalist and fashion-forward consumers.

Stars represent guidance, positivity, and individuality, making them easy to market across different regions. When produced as a stainless steel star charm necklace, the design benefits from clean edges, consistent weight, and excellent durability.

OEM/ODM manufacturers can offer various star charm interpretations, including flat polished stars, pavé-style stones, or brushed matte finishes. Pairing a star charm with a waterproof gold plated necklace base increases perceived value while maintaining functional benefits.

For wholesalers, star charm necklaces are ideal for year-round sales, as they are not tied to a specific season or holiday. This supports stable inventory turnover and repeat bulk orders.

Producing a reliable waterproof gold plated necklace requires strict process control at every stage. OEM/ODM factories typically start with material inspection to ensure stainless steel grades meet corrosion resistance standards, such as 304 or 316L.

After shaping and polishing, components undergo ultrasonic cleaning to remove oils and debris. The gold plating process, often PVD-based, creates a dense, uniform coating that bonds strongly to the steel surface. This method is key to achieving true waterproof performance.

Quality control teams then conduct adhesion tests, color consistency checks, and water exposure simulations. For designs like the 18k gold initial letter charm and stainless steel star charm necklace, attention is given to edges and engraved areas, where plating failure is most likely to occur.

Consistent QC standards help B2B clients confidently market their products as waterproof and long-lasting, reducing reputational risk and enhancing customer satisfaction.

One of the biggest advantages of stainless steel OEM/ODM production is cost efficiency. Compared to solid gold or vermeil, a waterproof gold plated necklace offers similar visual appeal at a fraction of the cost, making it suitable for mid-range and mass-market positioning.

Low MOQ programs allow startups and growing brands to launch collections featuring an 18k gold initial letter charm or stainless steel star charm necklace without committing to large volumes. This flexibility supports faster product testing and quicker response to market trends.

For established wholesalers, high-capacity factories can scale production rapidly, ensuring consistent supply during peak sales periods. Transparent pricing structures and efficient tooling further improve margins across the supply chain.

Beyond manufacturing, many stainless steel jewelry suppliers now offer integrated design services. This includes trend analysis, CAD development, and material recommendations tailored to target markets. For example, combining a waterproof gold plated necklace with interchangeable charms can increase average order value.

Design teams work closely with clients to refine products like the 18k gold initial letter charm, ensuring font readability and aesthetic balance. Similarly, star motifs can be adjusted in size and thickness to align with brand identity.

By partnering with experienced OEM/ODM manufacturers, B2B clients gain access to both technical expertise and market insights, supporting long-term brand growth rather than one-off product launches.

The growing popularity of waterproof jewelry presents a clear opportunity for brands, wholesalers, and distributors. A well-made waterproof gold plated necklace meets modern consumer expectations for durability, style, and convenience.

By leveraging stainless steel manufacturing, customizable options like the 18k gold initial letter charm, and trending designs such as the stainless steel star charm necklace, B2B clients can create versatile collections with strong commercial appeal.

Choosing the right OEM/ODM partner ensures consistent quality control, flexible MOQs, and scalable production capacity. In a competitive market, these factors are essential for building trust, reducing costs, and driving sustainable business growth.