Elevating Custom Charm Necklaces: Advanced Materials and Eco-Friendly Manufacturing

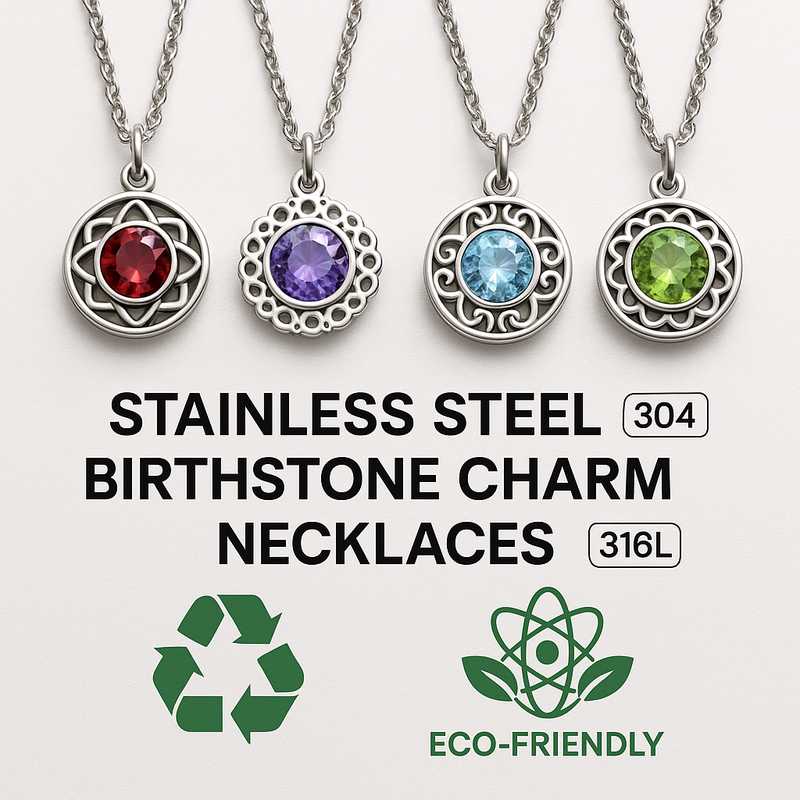

Discover the cutting-edge technologies in stainless steel selection, laser cutting, and sustainable production for superior birthstone jewelry manufacturing.

Introduction: The Future of Custom Birthstone Jewelry

In today’s competitive jewelry market, customization is key, and birthstone charm necklaces are among the most popular products in the industry. Whether for personal use or as a thoughtful gift, these necklaces carry a deep meaning for the wearer, often symbolizing their birth month, personal connections, or milestones. However, as consumer demand grows, so does the need for innovation in materials and manufacturing techniques to produce these custom pieces efficiently and sustainably.

For B2B businesses in the custom jewelry sector, selecting the right materials and adopting advanced manufacturing methods can significantly elevate the quality, durability, and appeal of birthstone necklaces. This article will explore the importance of stainless steel in custom jewelry production, focusing on two of the most commonly used alloys, 304 and 316L stainless steel. We’ll also delve into the technologies behind the manufacturing process, including laser cutting and hydraulic pressing, and how eco-friendly methods such as green electroplating and waste recycling are shaping the future of jewelry manufacturing.

Understanding Stainless Steel: A Comparison of 304 and 316L Alloys

When it comes to crafting high-quality birthstone charm necklaces, the choice of material plays a pivotal role. Stainless steel, known for its strength, durability, and aesthetic appeal, is a popular option in the jewelry industry. However, not all stainless steel alloys are created equal. The two most common grades used in jewelry production are 304 and 316L stainless steel. While both materials share some similarities, they differ significantly in terms of corrosion resistance, applications, and overall performance.

Corrosion Resistance: A Critical Factor for Jewelry Durability

304 stainless steel, also known as 18/8 steel, is highly resistant to corrosion, making it suitable for a variety of applications in the jewelry industry. However, it is not entirely immune to corrosion in harsh environments, particularly when exposed to chlorides or high levels of salt, such as in marine or coastal regions. This makes it a more cost-effective option for jewelry that is worn occasionally but may not withstand constant exposure to the elements.

On the other hand, 316L stainless steel, often referred to as marine-grade stainless steel, offers superior corrosion resistance compared to 304. This alloy contains molybdenum, which helps prevent rust and corrosion caused by harsh chemicals, saltwater, and acids. As such, 316L is the ideal choice for jewelry designed for daily wear or for customers in coastal areas or humid environments. Its high resistance to pitting and crevice corrosion ensures that birthstone charm necklaces remain pristine for longer periods, even in challenging conditions.

Application Scenarios and Cost Considerations

While 304 stainless steel is suitable for fashion jewelry that is worn occasionally or under controlled conditions, 316L stainless steel is the material of choice for high-end, durable custom birthstone necklaces. Its superior corrosion resistance, combined with its hypoallergenic properties, makes it perfect for customers with sensitive skin or those seeking long-lasting jewelry. However, 316L steel tends to be more expensive than 304, and its processing requires more advanced techniques.

Revolutionizing Jewelry Manufacturing with Laser Cutting and Hydraulic Pressing

In the manufacturing process of custom birthstone charm necklaces, precision is paramount. Laser cutting and hydraulic pressing are two technologies that have revolutionized the industry, allowing manufacturers to produce intricate designs and high-quality products with remarkable efficiency.

Laser Cutting: Precision and Intricate Design

Laser cutting is one of the most advanced and precise techniques used in jewelry manufacturing today. By utilizing focused laser beams, manufacturers can achieve incredibly detailed and intricate designs with minimal material wastage. This technology allows for the creation of birthstone charms with personalized engravings, intricate patterns, and delicate shapes, all while maintaining high levels of accuracy. The ability to create custom designs with laser cutting also reduces the need for costly molds and tooling, offering significant savings in the manufacturing process.

Laser cutting is especially valuable when working with stainless steel, as it ensures that even the finest details can be achieved without compromising the material’s integrity. It is particularly useful for custom birthstone necklaces, where intricate personalization is key. Additionally, laser cutting is a non-contact process, reducing the risk of distortion or damage to the jewelry during production.

Hydraulic Pressing: Efficiency and Consistency

Hydraulic pressing is another essential technology used in the creation of custom birthstone necklaces. This process involves applying controlled pressure to a piece of metal using hydraulic force, which allows manufacturers to form and shape the metal with precision. Hydraulic pressing is ideal for creating larger components or for mass-producing certain elements of a necklace, such as links or pendants, with consistent results. It also plays a crucial role in shaping and securing the birthstone within its setting, ensuring both structural integrity and aesthetic appeal.

Eco-Friendly Jewelry Manufacturing: Sustainable Practices for a Greener Future

As environmental concerns continue to grow, jewelry manufacturers are under increasing pressure to adopt more sustainable practices. Eco-friendly production methods not only help reduce the environmental impact of manufacturing but can also improve a brand’s reputation and appeal to environmentally-conscious consumers.

Waste Recycling: Minimizing Environmental Impact

One of the most effective ways to reduce the environmental impact of jewelry manufacturing is through waste recycling. Stainless steel is a highly recyclable material, and many manufacturers are incorporating recycling processes into their production lines. By recycling scrap metal and reusing materials, manufacturers can minimize the need for raw materials, reduce energy consumption, and cut down on waste. This approach not only benefits the environment but also helps businesses reduce production costs, making it a win-win situation for both manufacturers and customers.

Green Electroplating: Sustainable Finishing Techniques

Electroplating is a widely used technique in jewelry manufacturing to add color, shine, and durability to the finished product. However, traditional electroplating processes can be harmful to the environment due to the use of toxic chemicals and heavy metals. To address this, many jewelry manufacturers are adopting green electroplating technologies, which utilize non-toxic and environmentally friendly chemicals to achieve the same high-quality finishes without the harmful byproducts.

Green electroplating not only contributes to a cleaner manufacturing process but also ensures that custom birthstone necklaces have a durable and attractive finish that lasts longer. This method can be used to apply coatings on both 304 and 316L stainless steel, providing a range of colors and finishes while maintaining the material’s integrity and corrosion resistance.

Conclusion: Innovating for a Sustainable and High-Quality Future

The custom birthstone charm necklace market is evolving, with advancements in materials, manufacturing techniques, and sustainable practices paving the way for high-quality, durable, and eco-friendly jewelry. By embracing superior materials like 316L stainless steel, cutting-edge technologies such as laser cutting and hydraulic pressing, and implementing green manufacturing processes, businesses can offer their customers products that are not only aesthetically pleasing but also built to last and produced with minimal environmental impact.

For B2B customers in the jewelry industry, now is the time to invest in these advanced materials and sustainable technologies to stay ahead of the curve. By prioritizing quality, precision, and sustainability, businesses can differentiate themselves in the competitive custom jewelry market and build long-term relationships with eco-conscious consumers. Embrace innovation, elevate your designs, and lead the way to a more sustainable future in custom birthstone jewelry.

Ready to Enhance Your Custom Jewelry Line? Contact Us Today!

If you’re looking to incorporate advanced materials and sustainable practices into your jewelry manufacturing process, we are here to help. Reach out to us to explore how our OEM/ODM services can take your custom birthstone necklaces to the next level.