The global demand for meaningful, symbolic jewelry has surged in recent months, with spiritual personalization becoming a key driver of sales growth. Among these trends, the personalized angel number necklace has emerged as a fast-moving product category for jewelry brands and retailers seeking differentiation. For OEM/ODM stainless steel jewelry businesses, this trend presents a clear opportunity to offer scalable customization, durable materials, and attractive margins.

Angel number jewelry resonates strongly with younger consumers who value self-expression, spirituality, and layered styling. When combined with reliable manufacturing and cost-effective materials, this category can become a long-term revenue pillar for wholesalers and distributors. Stainless steel, especially with advanced surface treatments, plays a critical role in meeting both aesthetic and durability expectations.

In the past month, social media platforms and e-commerce marketplaces have shown increased engagement around angel number designs, particularly necklaces that allow personalization. A personalized angel number necklace aligns perfectly with the growing demand for emotional value and storytelling in accessories, making it a strong candidate for private label and OEM expansion.

For B2B buyers, this momentum means faster sell-through rates and broader customer appeal. Unlike trend-driven fashion jewelry with short lifecycles, angel number collections often enjoy repeat purchases and gifting demand. Manufacturers that can offer consistent quality and flexible customization gain a competitive advantage.

Stainless steel is especially suitable for this segment due to its long-lasting wear, resistance to tarnish, and ability to support fine engraving or laser marking. These technical benefits allow brands to promise durability without inflating retail prices.

From a production standpoint, stainless steel offers unmatched efficiency for large-scale jewelry manufacturing. It supports precision cutting, stamping, and engraving processes essential for creating a detailed personalized angel number necklace while maintaining tight tolerances across high volumes.

Compared to traditional precious metals, stainless steel significantly reduces raw material costs. This cost efficiency allows OEM/ODM clients to invest more in design service, branding, and packaging while keeping unit prices competitive. It also supports low MOQ strategies for brands testing new markets.

Additionally, stainless steel aligns with sustainability trends. Its recyclability and long lifespan help brands position their collections as responsible choices, an increasingly important factor in B2B purchasing decisions.

A gold plated stainless steel charm offers the visual appeal of fine jewelry while maintaining the structural strength of steel. Advanced PVD and electroplating technologies enable manufacturers to achieve rich gold tones with excellent adhesion and wear resistance.

For angel number collections, charms are often the focal point of the necklace. Using a gold plated stainless steel charm allows brands to create premium-looking pieces suitable for daily wear. This balance of aesthetics and durability directly supports higher customer satisfaction and lower return rates.

From a quality control perspective, stainless steel charms provide consistent surfaces that improve plating uniformity. OEM factories can implement standardized thickness testing and salt spray testing to ensure plating longevity, which is critical for wholesale distribution.

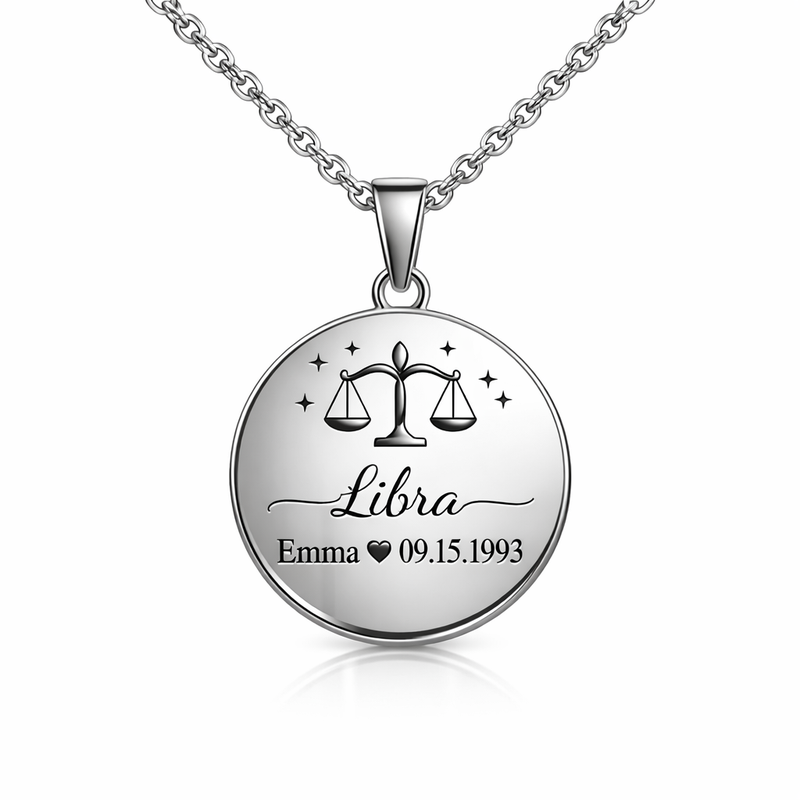

Customization is at the heart of the personalized angel number necklace trend. OEM/ODM manufacturers can offer multiple personalization methods, including laser engraving, embossed numbers, or modular charm systems. These options allow brands to tailor collections to different demographics and price points.

Design flexibility also extends to finishes and shapes. A gold plated stainless steel charm can be combined with polished, brushed, or matte textures to create unique visual identities. This helps retailers avoid product homogenization in crowded online marketplaces.

For wholesalers, offering pre-designed templates with customizable elements reduces lead times and simplifies inventory planning. This approach supports faster market entry while still delivering a personalized consumer experience.

The rise of layered jewelry styling has made the layering angel number necklace a strategic product for brands focused on upselling and cross-selling. Layering sets encourage customers to purchase multiple pieces, increasing average order value.

From a manufacturing standpoint, layering angel number necklace collections require careful consideration of chain lengths, charm proportions, and weight balance. Stainless steel provides the strength needed for thinner chains without compromising durability.

OEM partners can support brands by developing coordinated layering systems, such as adjustable chains or compatible charm sizes. This level of design service enhances brand cohesion and supports long-term customer loyalty.

Consistent quality is essential when producing personalized jewelry at scale. For a personalized angel number necklace, accuracy in number engraving and alignment directly impacts perceived value. Leading manufacturers implement multi-stage inspections, from raw material verification to final assembly checks.

Production capacity also matters for B2B clients planning seasonal launches or promotional campaigns. Stainless steel jewelry factories equipped with automated cutting and engraving machines can handle large orders while maintaining uniformity.

When producing gold plated stainless steel charm components, strict process control ensures color consistency across batches. This reliability is critical for distributors supplying multiple retail channels.

For jewelry brands and retailers, partnering with an experienced OEM/ODM supplier enables faster response to market trends like the layering angel number necklace. Low MOQ options allow brands to test new designs without heavy upfront investment.

Manufacturers can further support business growth by offering integrated services, including CAD design, sampling, packaging solutions, and logistics coordination. These value-added services simplify sourcing and strengthen long-term partnerships.

In competitive markets, speed and flexibility often determine success. Stainless steel jewelry manufacturing, with its efficient workflows and material stability, provides the foundation for scalable wholesale operations.

The personalized angel number necklace trend represents more than a short-term fashion wave. It reflects a broader shift toward meaningful, customizable accessories that resonate across global markets. For OEM/ODM stainless steel jewelry businesses, this creates a sustainable growth opportunity.

By leveraging durable materials, advanced plating techniques, and flexible customization, manufacturers can deliver high-quality solutions such as the gold plated stainless steel charm and coordinated layering angel number necklace collections. These capabilities help B2B clients strengthen their brand positioning and expand market share.

As demand continues to rise, investing in quality control, design service, and scalable production will ensure long-term success. Stainless steel remains a strategic material choice for businesses aiming to balance cost efficiency, durability, and modern design in the evolving jewelry landscape.