Personalized jewelry is having a fresh surge going into 2026, with initials, symbolic motifs, and “daily-wear” durability driving repeat purchases. For B2B buyers, the opportunity is clear: products that look premium, layer easily, and survive real life without constant returns.

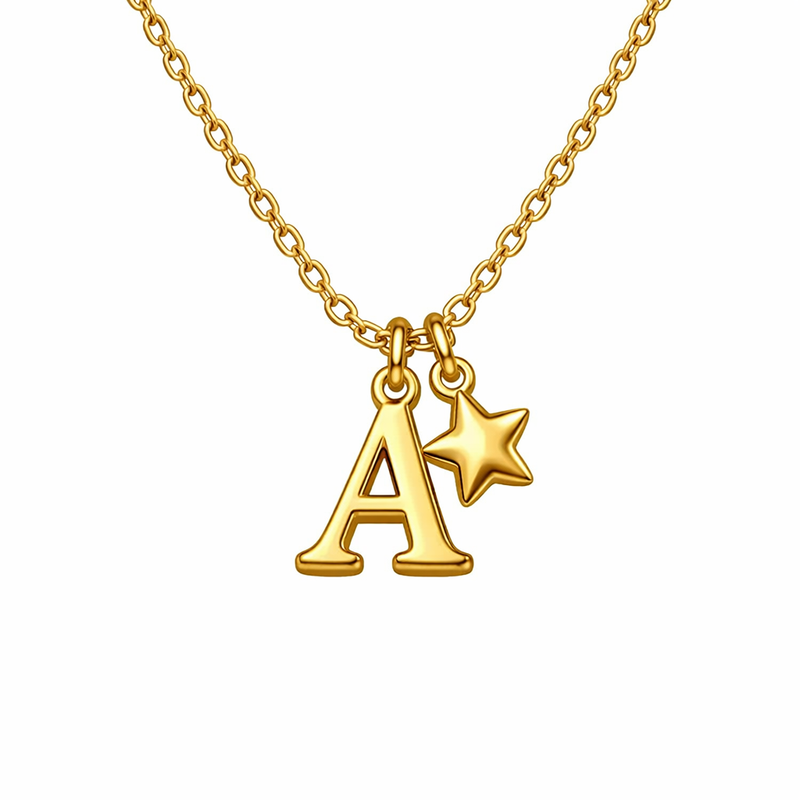

That’s why the waterproof 18k gold plated initial letter star necklace is moving from a cute add-on to a core SKU for brands, retailers, and wholesalers. When executed in stainless steel with the right coating and quality control, it can deliver the luxury look customers want, with the performance they now expect from everyday jewelry.

In this article, you’ll get a manufacturing-focused breakdown of how to build a scalable program around initials and stars, how to position a layering assortment for business growth, and what to ask your OEM/ODM factory to ensure durability, consistency, and smooth replenishment.

Initial jewelry keeps trending because it’s personal without being complicated. Add a star motif and it becomes instantly giftable, photo-friendly, and easy to style. Add “waterproof” and you remove the biggest friction point in fashion jewelry: customers don’t want to take necklaces off for showers, workouts, or beach days.

For brands, a waterproof gold letter charm necklace line is a high-frequency reorder category. Consumers buy multiple letters (their own, partner, kids), then stack them with symbols. Retailers love it because it supports attachments, cross-sells, and seasonal drops without redesigning the entire collection.

For OEM/ODM buyers, the business case is even stronger. A well-planned stainless steel initial charm layering necklace program lets you share chains across multiple charms, standardize jump rings, and simplify packaging—reducing cost per unit while expanding the visual assortment on your sales floor or website.

If you want to sell “waterproof” confidently, you need a base metal that won’t punish you with rust, weak plating adhesion, or unpredictable reactions to sweat and salt. Stainless steel is the most practical foundation for scale because it’s stable, strong, and consistent across large batches when your sourcing is controlled.

The key is choosing the right grade and surface prep. Many factories default to 304 for fashion jewelry due to cost, but 316L is often preferred for skin contact and corrosion resistance. For a waterproof 18k gold plated initial letter star necklace, 316L can reduce complaints around discoloration and improve long-term wear in humid climates.

Surface preparation matters as much as the steel grade. Polishing, ultrasonic cleaning, and degreasing must be standardized so the coating bonds evenly. If you’re building a waterproof gold letter charm necklace collection for multiple markets, insist on consistent pre-treatment specs and batch documentation.

“18k gold plated” can mean very different things depending on process control. For waterproof positioning, your goal is not just a golden color—it’s adhesion, abrasion resistance, and stable color over time. Most B2B programs use either traditional electroplating or PVD-based coating systems over stainless steel.

Electroplating can work well if thickness is controlled and sealing steps are done properly. However, for demanding wear claims, many brands prefer PVD coatings because they tend to be harder and more resistant to daily friction. A factory that can manage both methods gives you flexibility for different price tiers.

When developing a stainless steel initial charm layering necklace, consider building a two-level assortment: a value line using optimized electroplating and a premium line using higher-performance coatings. This supports upsells without forcing you to abandon margin-friendly entry SKUs.

To keep the waterproof 18k gold plated initial letter star necklace looking premium, you should also define color targets and allowable tolerance. “18k” is a look as well as a label—if one batch skews too yellow and the next is too pale, you’ll feel it immediately in returns and negative reviews.

Layering is not just styling—it’s a merchandising system. Your goal is to make it easy for customers to build sets (and for you to sell sets). A strong stainless steel initial charm layering necklace assortment typically includes 2–3 chain types, a controlled charm size range, and consistent bail or jump-ring geometry.

Start with chain lengths that stack cleanly (for example, short collar + mid length + long drop). Then standardize charm attachment so letters and stars can move across chains. This modular approach reduces tooling cost and expands SKU count quickly, which is ideal for low MOQ programs.

For the waterproof 18k gold plated initial letter star necklace, keep the star proportion balanced with the letter. If the star is too large, it dominates; too small, it disappears in product photography. Many brands succeed with a star that reads clearly on camera but stays lightweight for comfort.

Don’t forget functional details: rounded edges for skin comfort, reinforced jump rings, and bail openings designed for automated assembly. These “invisible” decisions protect your brand when the product becomes a daily staple rather than an occasional accessory.

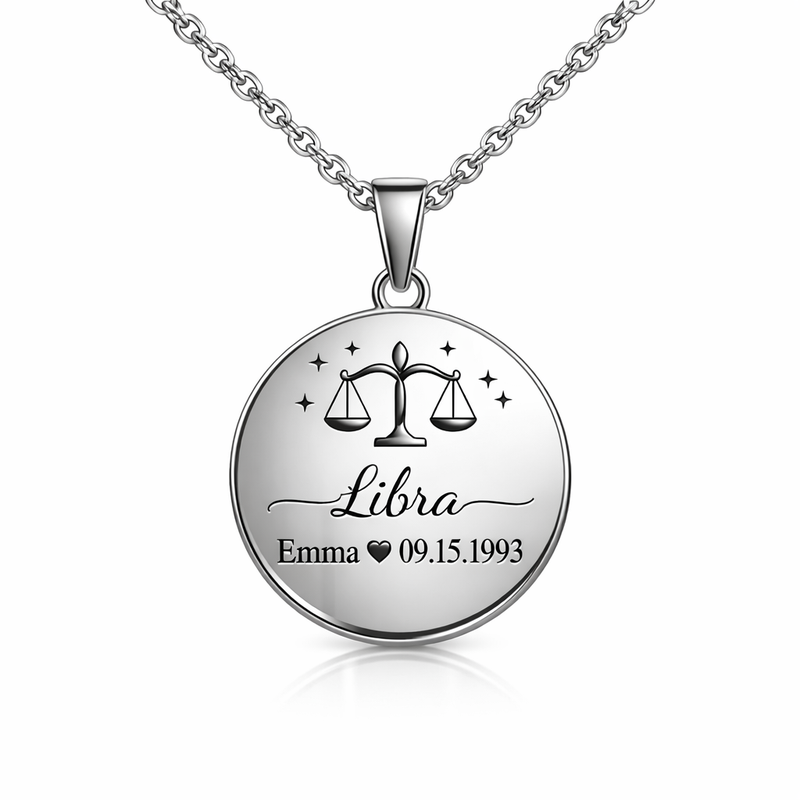

Customization sells, but only if your factory can deliver it consistently. For initial programs, the most scalable customization is a controlled alphabet set with standardized dimensions, paired with optional add-ons like stars, birthstones (synthetic), or engraved discs.

If you want faster development, ask for a design service that includes 3D modeling, rapid sampling, and a clear revision policy. With a waterproof gold letter charm necklace program, small differences in letter thickness or loop placement can affect how it lays on the body—so prototyping is worth it.

For OEM/ODM buyers, packaging customization is also a growth lever. Branded cards, barcode-ready labeling, and set-bundling options help you sell the stainless steel initial charm layering necklace as a giftable system, not just a single item.

To keep customization from blowing up complexity, structure your catalog in modules: choose a limited number of chain bases, a single ring standard, and a defined charm library. This reduces lead times and helps your factory plan production capacity without constant line changes.

“Waterproof” is a promise that must be backed by process control. In practice, you’re testing resistance to sweat, water exposure, and abrasion, plus verifying coating adhesion and color stability. Your OEM/ODM partner should be able to explain their test methods and provide records by batch.

For a waterproof 18k gold plated initial letter star necklace, prioritize these QC checkpoints:

Also insist on visual standards: color master samples, acceptable scratch thresholds, and plating thickness guidelines. These details protect your waterproof gold letter charm necklace positioning and keep your reviews strong as volume grows.

Finally, ask how the factory controls mixing across batches—especially when you run multiple letters. A stainless steel initial charm layering necklace set looks “cheap” if one letter is brighter or darker than the others, even if each piece is technically within range.

Many B2B buyers want low MOQ to test demand, but they also need consistent finish and stable lead times. The best approach is to plan a “core + expansion” production model: keep core chains and top letters in steady inventory, then produce long-tail letters in planned mini-batches.

For a waterproof 18k gold plated initial letter star necklace launch, you can start with a focused set (top-selling letters + star + 1–2 chain types) and expand after you see conversion. This helps the factory maintain quality control while you validate pricing and positioning.

From a production capacity standpoint, stainless steel programs scale well when you standardize components. If multiple SKUs share the same chain, clasp, extender, and plating color, you reduce setup time and improve yield. That’s how a stainless steel initial charm layering necklace becomes a reliable replenishment category, not a one-off seasonal hit.

To avoid bottlenecks, clarify upfront: daily output for chain assembly, charm casting/stamping capacity, coating line throughput, and final inspection staffing. These details matter when your waterproof gold letter charm necklace starts selling faster than expected and you need quick restocks.

Once manufacturing is locked, the next advantage is how you sell the story. Position the collection as a “wear-everywhere” personalization system: shower-safe, gym-friendly, vacation-ready, and designed to layer. This language supports higher perceived value and reduces hesitation.

Merchandise it as sets. A single waterproof 18k gold plated initial letter star necklace is a good start, but bundles drive margin: letter + star + second chain, or “family initials” multi-charm packs. For wholesale clients, provide ready-to-sell planograms and suggested SKU mixes by store size.

Content strategy also matters in B2B. Offer your retail partners short videos and photo packs showing layered looks, close-ups of finish quality, and simple durability demonstrations. That makes it easier for them to push the waterproof gold letter charm necklace story without producing everything themselves.

Finally, keep your line refreshes simple: seasonal star variations (north star, tiny sparkle), limited-edition textures, or new chain profiles. You can keep the core stainless steel initial charm layering necklace system intact while still giving customers reasons to return.

The market is rewarding jewelry that feels personal, layers effortlessly, and holds up to daily life. A well-made waterproof 18k gold plated initial letter star necklace is more than a trend item—it can be a repeatable business engine when supported by modular design, smart coating choices, and strict quality control.

If you’re sourcing OEM/ODM, focus on the fundamentals: stainless steel stability, coating performance, standardized components, and documented testing. Do that, and your stainless steel initial charm layering necklace assortment can scale from low MOQ trials to large wholesale runs without quality drifting.

Most importantly, treat “waterproof” as a manufacturing discipline, not a marketing phrase. When your factory can consistently deliver a durable finish, your waterproof gold letter charm necklace line earns trust, reduces returns, and supports long-term brand growth.