The first weeks of 2026 are already showing a clear direction in fashion jewelry demand: consumers want pieces that look premium, layer effortlessly, and survive real life. That’s why the waterproof gold plated necklace category is moving from a niche feature to a mainstream requirement for brands and retailers.

At the same time, charm-focused designs are surging because they feel personal, giftable, and easy to refresh seasonally. In B2B terms, this is ideal: you can build multiple SKUs from one base chain using modular charm sets, reducing development cost while increasing sell-through.

If you’re sourcing for 2026 launches, the sweet spot is stainless steel jewelry engineered for durability, then finished with high-quality gold plating for a luxury look. This article breaks down how OEM/ODM partners can help you scale fast with reliable production, customization options, and consistent quality control.

Trends are shifting toward jewelry that can be worn everywhere—poolside, at the gym, during travel, and through everyday routines. A waterproof gold plated necklace speaks directly to that lifestyle, helping brands compete in a market where consumers are more educated and less tolerant of tarnish or fading.

From a manufacturing perspective, “waterproof” doesn’t mean the same thing across all factories. For B2B buyers, what matters is performance under repeated exposure to water, sweat, salt, and cosmetics. The best OEM/ODM suppliers define waterproof standards clearly, then back them with testing and process controls.

Stainless steel is a natural foundation because it resists corrosion better than many base metals. When combined with strong surface preparation and advanced coating methods, you can confidently market a waterproof gold plated necklace as a long-wear product that supports higher retail pricing and stronger repeat purchase rates.

In 2026, layering and daily-wear styling continue to dominate social content. That means necklaces will face constant friction from skin, fabric, and pendants. Choosing the right plating thickness, topcoat, and charm attachment method is critical to reducing after-sales issues and protecting your margins.

Recent fashion coverage and social trend data continue to favor long necklace stacks and statement personalization. This directly benefits charm necklaces because they can be worn alone or layered, and they photograph well in short-form content. For B2B clients, this translates into faster product cycles and more repeat orders.

Two designs stand out for scalable brand-building: the 18k gold plated star charm necklace and the stainless steel initial letter charm necklace. Both are easy to position as gifts, self-expression pieces, and everyday staples.

The 18k gold plated star charm necklace works because star motifs stay relevant across seasons, from minimalist everyday fashion to festival looks. You can also adapt the star design into different sizes, textures, or stone-set versions without changing your core supply chain.

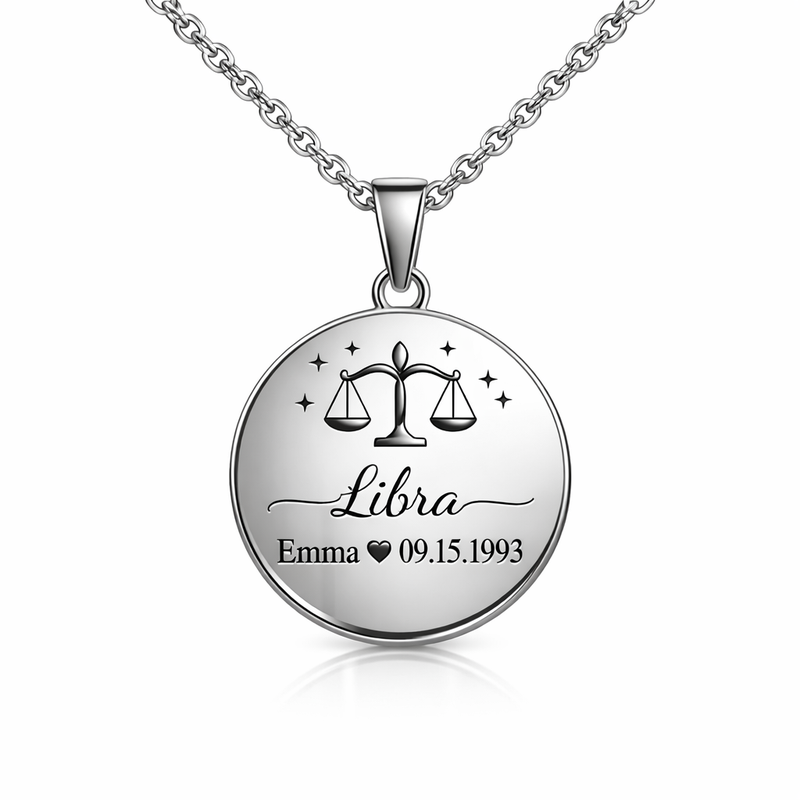

The stainless steel initial letter charm necklace is even more powerful for personalization. It supports A–Z expansions, add-on charms, and nameplate-inspired collections. For wholesalers and retailers, that means higher basket sizes and the ability to target multiple demographics with the same base product.

When both styles are made in stainless steel and engineered as long-wear products, they also pair perfectly with the waterproof gold plated necklace promise—making them easier to sell online with fewer quality concerns.

If you’re developing a true waterproof gold plated necklace, the best starting point is premium stainless steel such as 304 or 316L. Many brands prefer 316L for its stronger corrosion resistance and hypoallergenic reputation, especially for customers with sensitive skin.

Next comes plating. In stainless steel jewelry manufacturing, the most durable gold look is typically achieved through modern coating systems, often including PVD-based options. These can offer stronger adhesion and wear resistance compared to basic electroplating, depending on your factory’s equipment and process stability.

For an 18k gold plated star charm necklace, the charm edges and raised surfaces face the most abrasion. A strong OEM/ODM partner will adjust polishing, plating thickness, and protective topcoats to reduce premature fading. This is a detail that directly affects customer reviews and repeat orders.

For a stainless steel initial letter charm necklace, engraving depth and surface finishing also matter. A crisp initial must stay readable after long wear, so the charm should be designed with proper depth and clean edges, not shallow stamping that disappears over time.

When buyers ask for “18k gold plated,” it often refers to the color standard rather than solid gold content. Manufacturers should match tone consistency across batches using controlled solution management, bath monitoring, and standardized process parameters. This is a must for brands selling multiple SKUs and expecting uniform storefront visuals.

The biggest business advantage of charm necklaces is modularity. With the right design system, you can build a collection around one chain style and swap in multiple pendants. This reduces tooling costs and speeds up your product launch schedule.

For example, you can create a base waterproof gold plated necklace chain and then offer multiple charm options. That includes the 18k gold plated star charm necklace in different star silhouettes (flat, puffy, cutout, stone-set, engraved) and the stainless steel initial letter charm necklace in various font families and charm sizes.

Strong OEM/ODM design service should include CAD development, sampling, packaging support, and production engineering suggestions. If you’re targeting rapid growth, prioritize suppliers who can propose improvements that reduce weight, minimize defects, and improve assembly efficiency while maintaining the desired premium look.

Customization options B2B buyers typically request include:

When built correctly, one waterproof-focused line can support dozens of SKUs without creating supply chain chaos. That’s a practical path to growing wholesale accounts and improving reorder frequency.

Quality control is where B2B success is protected. Even the best marketing can’t save a collection if the plating fades quickly or the clasp fails. For a waterproof gold plated necklace, QC should prioritize performance in moisture, friction, and chemical exposure scenarios.

Many OEM/ODM factories offer standardized testing such as salt spray tests, abrasion testing, and basic sweat simulation. For brands selling a premium 18k gold plated star charm necklace, it’s worth setting clear testing targets aligned with your positioning—especially if you’re selling into markets with strong return policies.

Key QC checkpoints include raw material inspection, surface polishing consistency, plating adhesion, and color uniformity. For charm products, it also includes weld strength, jump ring closure integrity, and the reliability of charm connectors under repeated movement.

The stainless steel initial letter charm necklace needs extra attention for detail clarity. If the letter edges aren’t clean, the product can look “cheap” even if the material is premium. OEM/ODM manufacturers should use controlled molding/stamping and finishing methods that keep letters sharp without creating burrs.

Don’t overlook packaging QC. Scratches often happen after production, during packing and shipping. Protective films, individual polybags, and anti-tarnish packaging can reduce defects and improve customer unboxing experiences, especially for wholesale orders shipped in bulk.

For many brands, the top challenge is balancing trend response speed with inventory risk. A reliable supplier offering low MOQ production can help you test new charm variations without overcommitting cash flow.

Start with 2–4 hero products and build out. A core waterproof gold plated necklace chain can anchor the collection while you rotate charm drops each month. This is especially effective for the 18k gold plated star charm necklace, where new star textures and seasonal add-ons keep the design fresh.

For the stainless steel initial letter charm necklace, you can scale in phases. Begin with top-selling initials based on your market data, then expand to A–Z when demand is proven. This reduces the initial SKU burden while still giving customers personalization.

Cost efficiency comes from process repetition. If you standardize chain lengths, clasp types, plating colors, and packaging sizes, your factory can optimize production flow. Over time, this reduces per-unit labor time and improves yield, allowing you to compete more aggressively in wholesale pricing.

When discussing capacity, look beyond “monthly output.” Ask about lead time during peak seasons, plating line throughput, and the factory’s ability to handle multiple SKUs simultaneously while maintaining color matching. These details matter when you’re shipping bulk orders to distributors or retail chains.

Even the strongest product needs the right merchandising to win. For 2026, focus on story-driven charm collections: “stars for luck,” “initials for identity,” “waterproof for everyday confidence.” This helps retailers explain value quickly and improves conversion in short attention spans.

Bundle strategies are especially effective. Offer a waterproof gold plated necklace as the base, then sell charm add-ons to increase average order value. Customers often buy one necklace and add multiple charms, especially with initials.

Create clear tiering:

For wholesalers and distributors, consistent product photography and spec sheets matter. Request factory support for dimension charts, plating descriptions, and care instructions. Clear documentation reduces buyer hesitation and helps retailers sell with confidence.

Finally, consider regional preferences. Some markets prefer warmer gold tones, others prefer lighter champagne gold. A strong OEM/ODM partner should be able to provide color samples and match references across multiple production runs, especially if you’re expanding internationally.

The market direction is clear: durability and personalization are no longer “nice to have.” A well-made waterproof gold plated necklace line helps you reduce returns, improve reviews, and justify premium pricing—especially when supported by strong OEM/ODM manufacturing and quality control.

Charm-led bestsellers like the 18k gold plated star charm necklace and the stainless steel initial letter charm necklace are ideal for B2B growth because they’re modular, giftable, and easy to expand into a full collection with low development risk.

If you want to win wholesale accounts and keep reorders flowing in 2026, focus on three priorities: consistent plating durability, scalable customization options, and factory-backed QC standards. When those are locked in, you can confidently market your necklaces as long-wear essentials—built for real life and designed for business growth.